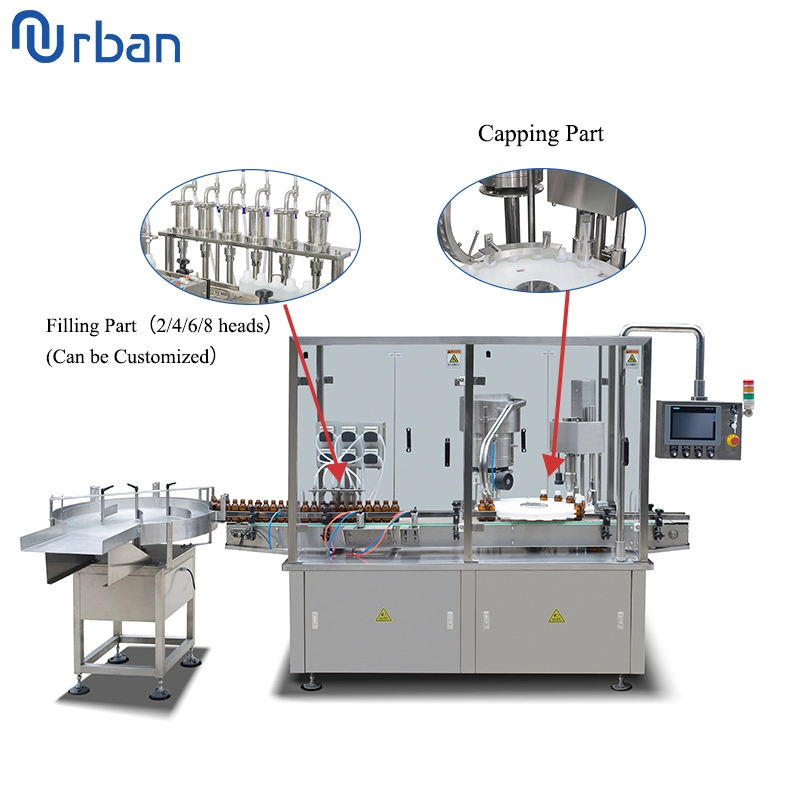

Automatic 2/4/6/8 heads liquid monoblock washing filling capping 3 in 1 machine

1. Filling form: servo-driven multi-head piston filling;

2. The maximum filling temperature is within 70℃;

3. Material in contact with liquid parts: 304# stainless steel and food grade PVC;

4. The filling nozzle is equipped with anti-dripping device to ensure the filling without drawing and leakage;

Product details

Filling

The size of the tray and the number of filling heads can be customized according to the needs of filling

Control

PLC touch screen control panel, visualization of working parameters, simple operation interface, and the fastest basis for machine conditions. 15 different national operating languages for wider applicability.

Product parameters:

| Production Capacity | 40-60 bottles/min or customized |

| Filling Volume | 50-500ml or customized |

| Filling Accuracy | ± 1% |

| Filling Head | 1 head or Customized |

| Capping Head | 1 head or Customized |

| Qualified Rate | ≥99% |

| Voltage | 380V 50Hz |

| Power | 2.5KW |

| Dimension | 2400*900*1700mm |

| Weight | 750KG |

Product description

Main Characteristic

1, PLC control, touch screen operation, simple and convenient.

2, Frequency control, production speed can be adjusted.

3, High precision CAM divider provides accurate positioning.

4, Filling and capping in one machine.

5, Using SUS304 & SUS316, meet the GMP requirement.

4A SERVICE

* Free sample testing before order.

* Free spares provided for machines.

* Free machine training at factory / technician available for oversea service.

* One-to-one effective service within 12 hours.