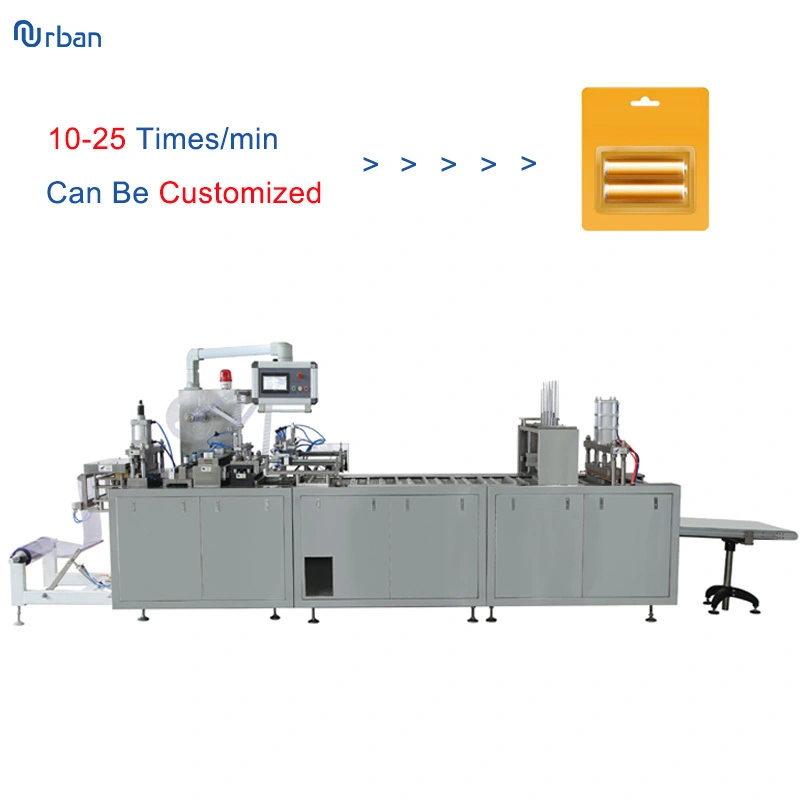

Automatic chain plate paper-plastic packaging machine BH-570D

This machine is suitable for paper-plastic packaging, such as Metal fittings(battery, electronics, glue); Stationary(pencil sharpener,eraser, correction fluid,solid glue); Motorcycle accessories(brake pad, sparking plug); Commodities(shaver, toothbrush, teat); Cosmetics(lipstick); Medicine(Safflower oil,Essential balm ); toys(toy car); Medical equipment; Food and etc.

Product details

It can be applied to the various kinds of packaging for products──

Metal fittings(battery,electronics,glue);Stationary(pencil sharpener,eraser, correction fluid,solid glue);motorcycle accessories(brake pad, sparking plug); Commodities(shaver,toothbrush,teat);Cosmetics(lipstick);Medicine(Safflower oil,Essential balm );toys(toy car); Medical equipment;Food and etc.

Product parameters:

|

Item |

Parameters |

|

|

Cutting Frequency |

10-25 times/min |

|

|

Adjustable Travel Range |

35-220mm |

|

|

Max. Forming Area |

490×220mm |

|

|

Max. Forming depth |

STANDARD MACHINE:38mm CUSTORM MACHINE:60mm |

|

|

Forming And Heating Power (Upper and Down) |

2.5KW(×2) |

|

|

Sealing and Heating Power |

4KW |

|

|

Total Power |

380V 50HZ(480V 50HZ)14KW |

|

|

Packaging material |

Roll |

≤400mm(Diameter)*500mm(Width)* 0.2-0.5mm(Thickness) |

|

Paper board |

≤570×222×0.5mm (L*W*H) |

|

|

Overall dimension |

(5900*1000*2000) mm (L*W*H) |

|

|

Weight |

2600Kg |

|

Product description

Main Performance Characteristic

〉The functions include positive/negative pressure molding, Butterfly hook punching(Optional),Cutting,Auto-feeding,Cards lowering,Heat sealing,and Output etc .

Simple structure and easy to operate.

〉With 304 stainless steal shell, which conforms to the GMP of national pharmaceutical industry,good shape, also easy to clean.

〉With imports frequency control of motor speed,colorful control panel(Human-computer interface),and PLC(Programmable Logic Controller System) that has high productivity with low noise. Simple operation process makes it more advantaged automation and humanization.

〉It uses servo motor drive steplessly and is easy to adjust; changing molds becomes easier, too.

〉Photoelectric control; the lack of PVC and cards can trigger buzzer alarm.

〉the separate-type design makes it convenient to transport and free out of the elevator.

〉Each material devices can save a large quantity of packaging materials.

〉Molds can be designed according to special needs and auto-feeding device is alternative.