The NJP-1200D automatic capsule filling machine produced by our company is the innovative product of the third generation. It not only covers all the functions and effects of the domestic capsule filling machine of the same model, but also has six pieces of innovation, two of which has been issued the utility model patent certificate by the national intellectual property administration, PRC at May 11, 2016. The innovative NJP-1200D automatic capsule filling machine has advantages of higher production efficiency and longer service life, and has been well received by customers at home and abroad.

|

Model

|

NJP-1500D

|

|

Filling capacity

|

90000pcs per hour

|

|

Weight

|

1000Kg

|

|

Dimension

|

1200×1000×2150mm

|

|

Power supply

|

380/220V 50Hz

|

|

Total power

|

5.5KW

|

|

Segment bores

|

9 holes

|

|

Vacuum

|

40m³/h-0.04-0.08Mpa

|

|

Dust collector

|

24.5Kpa 210m³/h

|

|

Air compression

|

Air consumption 5m³/h Pressure 5-7Kg

|

|

Water source

|

500L/h 0.1-0.2Mpa

|

|

Operating noise

|

<75DB(A)

|

|

Filling percentage

|

Empty capsule 99.9% filled capsule 99.8%

|

|

Capsule size

|

00,0,1,2,3,4,5#

|

|

Filling accuracy

|

Western medicine ±3% Chinese medicine ±4%

|

|

Suitable for

|

Powder, Granule, Pellet, Tablet.

|

The new hopper adopts butterfly valve-type powder feeding, and is very suitable for drug powder with poor liquidity, including Chinese herbal medicine and Chinese patent drug.

Due to that its vibration unit equipped will force the powder to run down, which has solved problem of failing to feed in powder that often happens in the traditional screw feeding device because of the poor liquidity of powder.

The new type seeder rack adopts guideway transmission mechanism, with high operation precision and long service life. The enclosed design prevents waste capsule and dust from entering, ensuring the rapid and orderly seeder and accurate capsule orientation.

Integrated powder aspirator

When the abnormal capsules cannot be separated normally, the powder entering into the lower mold hole is directly inhaled into the powder collector by the powder recovery device at the filling station, so as to prevent the powder from falling on the mechanical platform and avoid the waste and loss of powder.

Ten back to turntable frame is made of one-piece processing forming, do compact structure, no splicing gap, good sealing, easy disassembly, easy to maintain individual modules movement up and down (lower die do horizontal telescopic movement, the module for vertical lifting movement) and module of fixed bracket shaft seal used in oil, dustproof lips skeleton shield.

To achieve no noise, small volume, small load, high precision completely enclosed turntable inside three years, no maintenance, no refueling, no maintenance, no powder.(patent no. : ZL 2015 2 1021530.0).

Modular design, filling gripper pin positioning, no need to stop in production to adjust the load, the replacement of different types of filling rod fast and convenient.(patent no. : ZL 2015 2 1021519.4)

Filling pedestal adopts the design of negative pressure inside the base connected with powder collector, equipment under the high speed running state, a small amount of powder into the packing base, on the base hole can produce negative pressure make the powder to the recycling equipment, after filtration powder collector to collect collector, make the powder can be used for a second, avoid the waste of powder and erosion.

Slot lock capsule plate with flexible adjustable, capsule lock and not in place can be fine-tuned at any time, no need to adjust the station lever.

Using the technology of purifying compressed air and intermittent gas impingement, the problem that the capsule cannot be separated due to the strong hygroscopic property of the powder and its easy to stick to the upper and lower mold holes in the production process was solved, and the probability of capsule loading was effectively increased.

Using the current latest into the CAM drive system, transmission bracket up and down through the design

Running CAM all use the inner groove CAM, replace the honest external CAM, high-speed operation to fine, accurate, stable and noiseless.

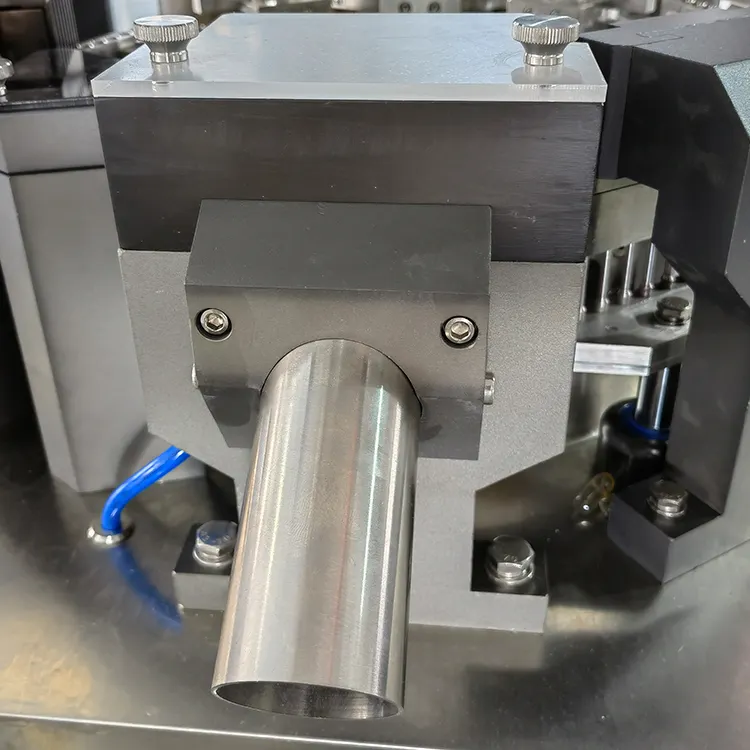

A New Type of Bladder Discharging Mechanism

The new type of finished product capsule discharging mechanism exclusively adopts the design of capsule clamping plate. When the finished product capsule discharging, there is no external air source, and no dust flying in the production process. At the same time, it can effectively avoid the mechanical injury of the finished product capsule when it is discharging.

Dry vacuum pump has the following advantages: 1. In the production process of equipment quiet effect is very good. 2. The vacuum generated by the dry vacuum pump through the eccentric slide high-speed rotation meets the international (FTA) pharmaceutical gas standards. 3. Continuous use of vacuum pump does not generate heat and will not affect the temperature control of GMP workshop. 4. The vacuum degree is sustainable and will not be reduced due to long time use. 5. Dry vacuum pump has its own impurity filtration system, which is simple and convenient to clean.

Company Advantages

· The designs of Urban Machinery best capsule filling machine vary with the changes in the market.

· best capsule filling machine has no pollution to environment which is more eco-friendly.

· The product is leading the market trend and has a bright market prospect.

Company Features

· Urban Machinery seized the favorable opportunity to achieve the rapid growth in the history of best capsule filling machine industry.

· Investing scientific research and development is critical for the development of Urban Machinery.

· We guarantee that best capsule filling machine meets local requirements. Please contact us!

Application of the Product

Our best capsule filling machine is widely used in various scenarios.

We have a professional team and can provide customers with the most appropriate solutions to help customers achieve their goals quickly and effectively.