Pharmaceutical Machines Manufacturers Bulk Buy Urban Machinery

Product parameters:

|

Model |

Unit |

Main Technical Parameters |

|

|

Maximum Punching Speed |

Time/Min |

150 |

|

|

Maximum Forming Depth |

mm |

12 |

|

|

Maximum Forming Area |

mm |

180×260(L×W) |

|

|

PVC (Thickness × Width) |

mm |

(0.25-0.35)×260 |

|

|

Aluminum Foil PTP (Thickness × Width) |

mm |

0.02×260 |

|

|

PVC Roll Outer Diameter |

mm |

<φ300 |

|

|

PTP Roll Outer Diameter |

mm |

<φ250 |

|

|

PVC & PTP Roll Core Diameter |

mm |

φ70~76 |

|

|

Dimensions (L×W×H) |

mm |

3130×1150×1900 |

|

|

Air Pressure |

Mpa |

Mpa 0.5-0.7Mpa Air Consumption: 0.2m³/min |

|

|

Cooling Water |

Mpa |

Mpa Water Pressure: 0.1-0.25Mpa Water Consumption: 0.01-0.02m³/min Circulating Cooling Water Tank or Tap Water |

|

|

Weight |

kg |

2600 |

|

Product description

1.The machine is a continuous operation, using automatic opening (sucking) box, manual folding (1-4 fold), feeding, feeding, batch number, sealing, detection and waste removal and other processes (can also be installed hot melt adhesive device), stable operation, easy to operate;

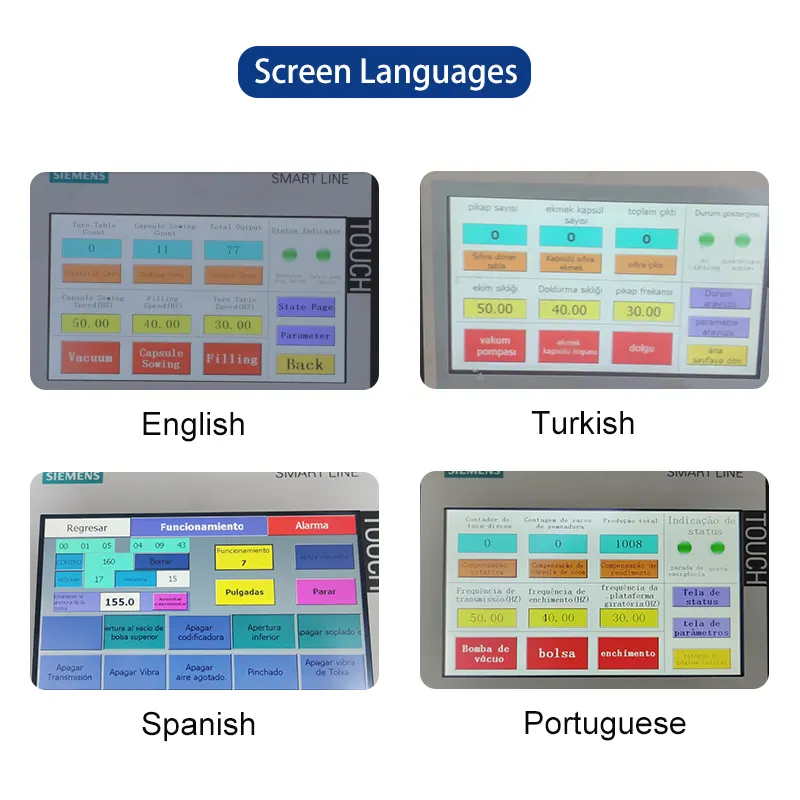

2.servo stepping, PLC and man-machine interface automatic control operating system, stepless frequency conversion speed regulation, high degree of automation;

3.has the overload protection system of the whole machine, the origami mechanism overload protection system, and the push hand overload protection system, which automatically stops when there is overload such as stuck delay, and displays the fault information on the touch screen, which is convenient for maintenance and troubleshooting, reduces the damage to the equipment, and ensures the safety of man and machine;

4.packaging program adopts the principle of packaging priority. When there is no packaging, no instruction manual is absorbed, no carton is absorbed, and no packaging is pushed to ensure the qualified product rate and reduce the waste of packaging materials.

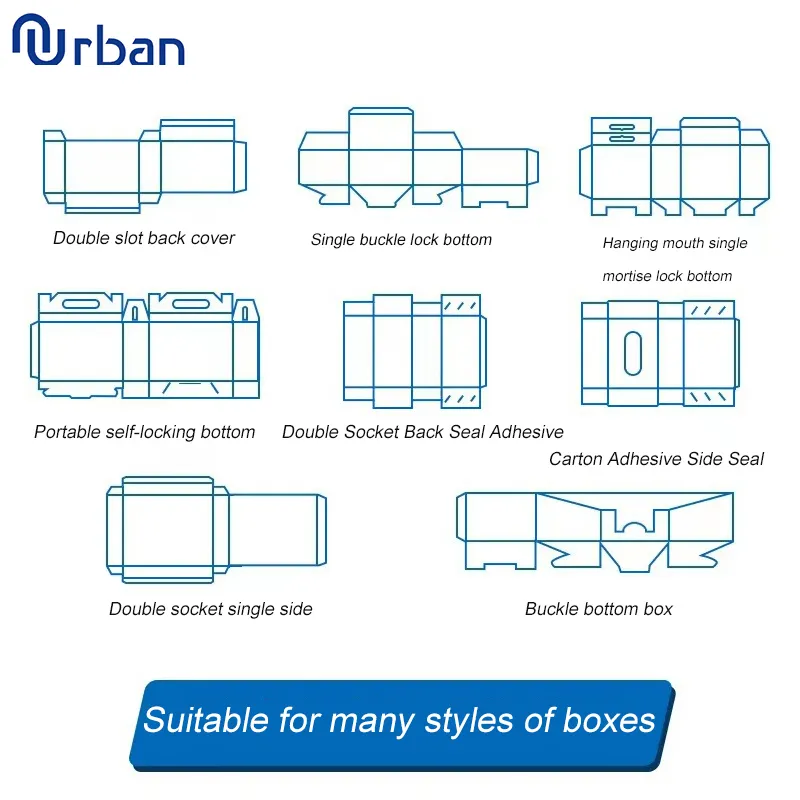

5.The variety of packaging, suitable for packaging medicine board, medicine bottles, pillow bags, flexible tubes, soft double aluminum plate, pellet bags, plastic trays, cosmetics, food and some electronic products and other industries;

6.Automatic stop without instruction manual for three consecutive times, automatic stop without carton and alarm.

7.can be designed according to customer requirements a variety of automatic feeder and conveying mechanism and other devices.

8.When the packaging is replaced within a certain range of specifications, there is no need to replace the mold, just simple adjustment.

9.can be connected with other supporting packaging production lines.

Company Advantages

· The production of Urban Machinery pharmaceutical machines manufacturers adopts lean production model.

· The product is carefully checked to ensure the maximized durability.

· Wenzhou Urban Machinery Co., Ltd. has very professional engineer team who can do the special design of products for you.

Company Features

· Wenzhou Urban Machinery Co., Ltd. is taking up a larger market share year by year for its pharmaceutical machines manufacturers.

· Urban Machinery actively introduces high-end talents.

· Our increased capacity leads to considerable cost reduction, thus we can offer the most competitive price for products with superior quality. Call!

Application of the Product

Urban Machinery's pharmaceutical machines manufacturers can be used in different industries to meet the needs of customers.

With professional engineers and technicians in our company, Urban Machinery is able to provide one-stop and comprehensive solutions for customers.