Tablet Blister Machine by Urban Machinery

Product details

Developed by our company's scientific research personnel on the basis of the standard model and combined with the feedback experience of many users in the course of many years of use. Integrated automatic control technology, a new generation of product with adjustable stroke and innovative design in strict accordance with industry standards .

Product parameters:

|

Production capacity |

10-15 times/min |

|

|

Use packaging materials and specifications |

Paper card: width 350mm thick 300-350g |

|

|

The maximum width of medicinal PVC is 350mm and the thickness is 0.25-0.40mm |

||

|

Travel adjustable range |

50mm-240mm |

|

|

Max. Forming depth |

30mm |

|

|

Maximum molding area (mm2) |

345×230×30mm |

|

|

Total power supply |

380V 50HZ 60HZ 11KW |

|

|

Air compressed required |

≥1m3/min |

|

|

Overall dimension |

5300×900×1650mm |

|

|

Weight |

1400Kg |

|

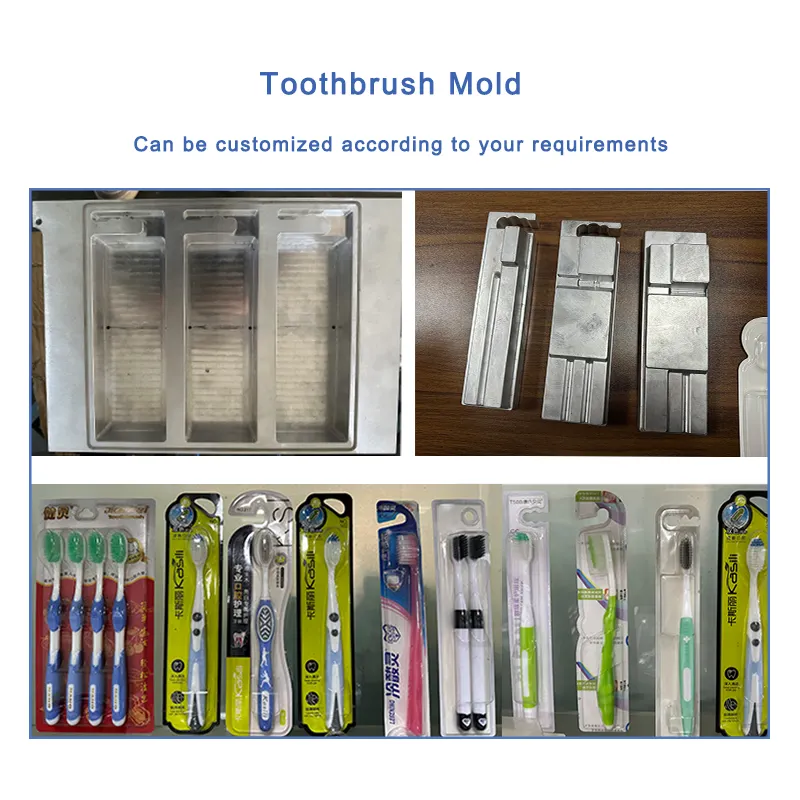

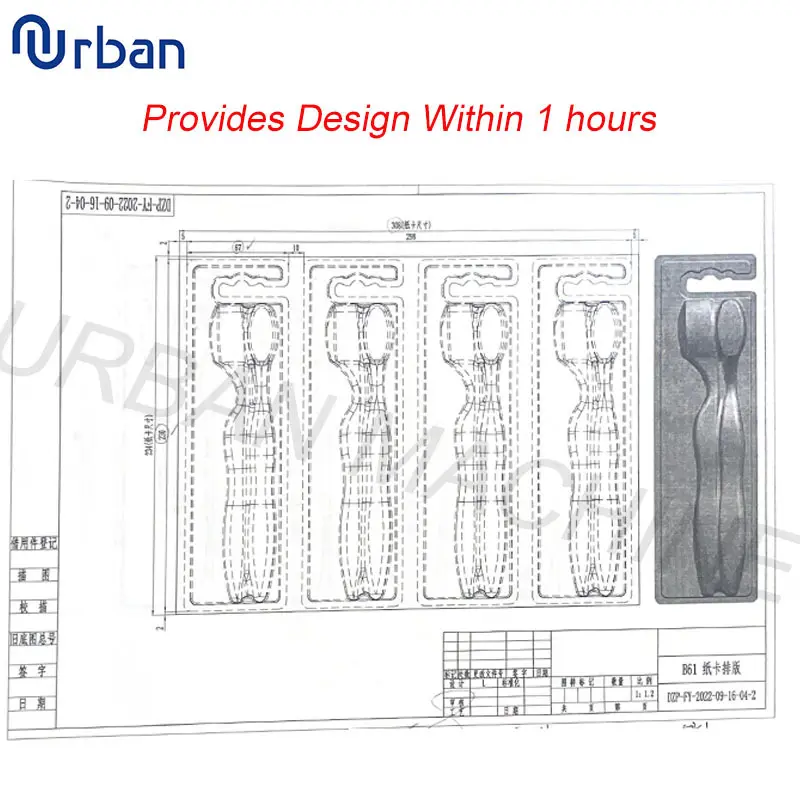

Product description

PVC preheating

Turn on the machine for heating, the upper and lower heating plates are closed, and the PVC plastic sheet is preheated between the upper and lower heating plates. After preheating, it enters the blister forming mold under the action of traction.

Blister forming

The forming upper mold is fixed, and the forming lower mold rises to the upper limit under the action of the cam and presses the PVC plastic sheet. At this time, the air valve is opened, and the compressed air passing through the filter pressure reducing valve enters the forming cavity of the forming lower mold through the forming upper mold, and the PVC plastic sheet is compressed. The sheet is formed by positive compression.

Item addition

After the PVC plastic sheet is formed into a specific shape, the feeder feeds the packaged items into the blister. Materials with special shapes are fed manually.

heat seal

Heat the PVC blister and the paper card after the material has been added, and use point sealing to bond the material so that the material is no longer in contact with the outside world.

small blanking

After the plate is heat-sealed, it is pulled to the small punching station, and the hook hole of the product is punched out to the desired shape.

Big blanking

The finished whole piece of PVC is punched and cut into blocks to meet the required dimensions before outputting.

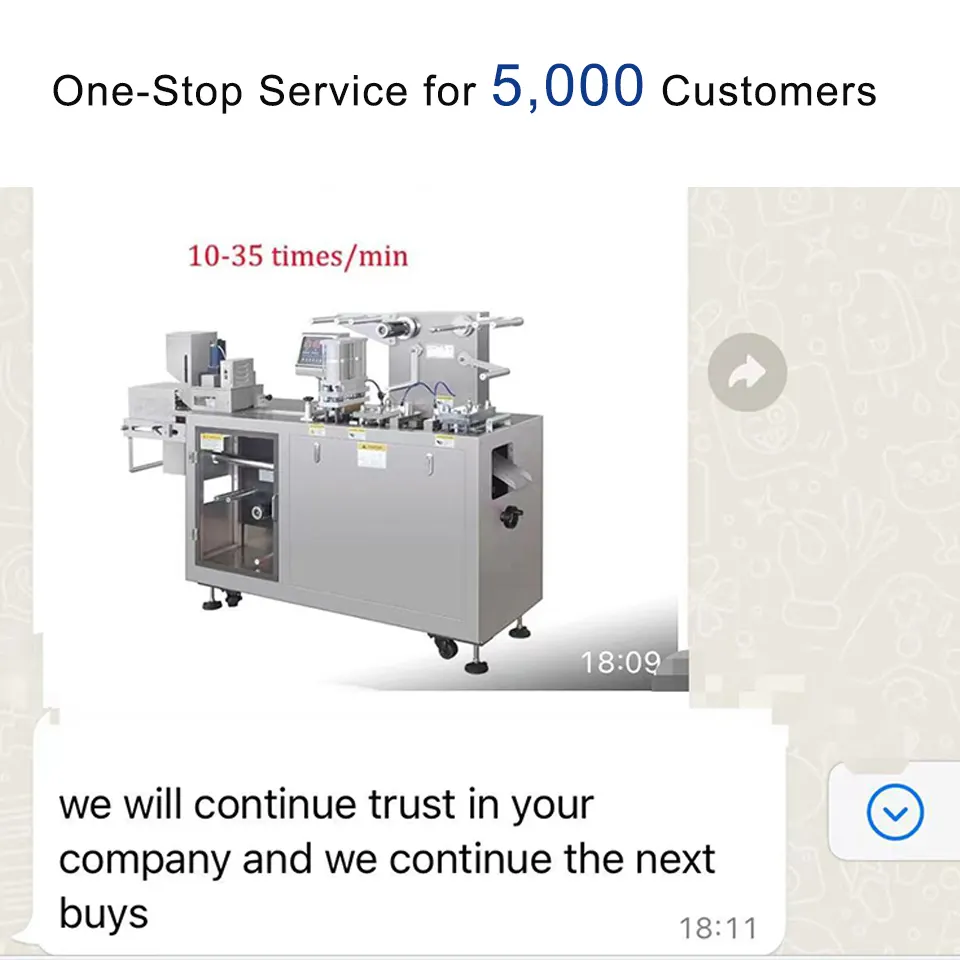

Company Advantages

· Wenzhou Urban Machinery Co., Ltd. adopts advanced production technology during the process of manufacturing tablet blister machine.

· The product is widely demanded in the global market and has the potential to be applied more in the future.

· Wenzhou Urban Machinery Co., Ltd. has gained outstanding reputation amongst the vast clients.

Company Features

· Wenzhou Urban Machinery Co., Ltd. is an outstanding manufacturer integrating development, design, production, and sales of tablet blister machine. We are one of the leading suppliers in the domestic market.

· Sophisticated technologies are being continuously completed in Urban Machinery.

· We assert both professional and ethical approach, coming from corporate values such as team cooperation, reliability, high quality, long-term cooperation, social responsibility, and sustainability. Get more info!

Application of the Product

The tablet blister machine produced by Urban Machinery is widely used in many industry sectors.

Guided by the actual needs of customers, Urban Machinery provides comprehensive, perfect and quality solutions based on the benefit of customers.