Wholesale Pharma Packaging Solution Urban Machinery Brand

Product details of the pharma packaging solution

Quick Detail

Urban Machinery pharma packaging solution features scientific structure and aesthetic appearance. It is well-designed by our dedicated designers who are equipped with innovative design ideas. The product comes up to the standards in terms of quality and performance. pharma packaging solution of Urban Machinery is widely used and has a wide range of applications. The product caters to the market requirements and is going to be more widely used in the market.

Product Introduction

Our pharma packaging solution are perfect in every detail.

Product details

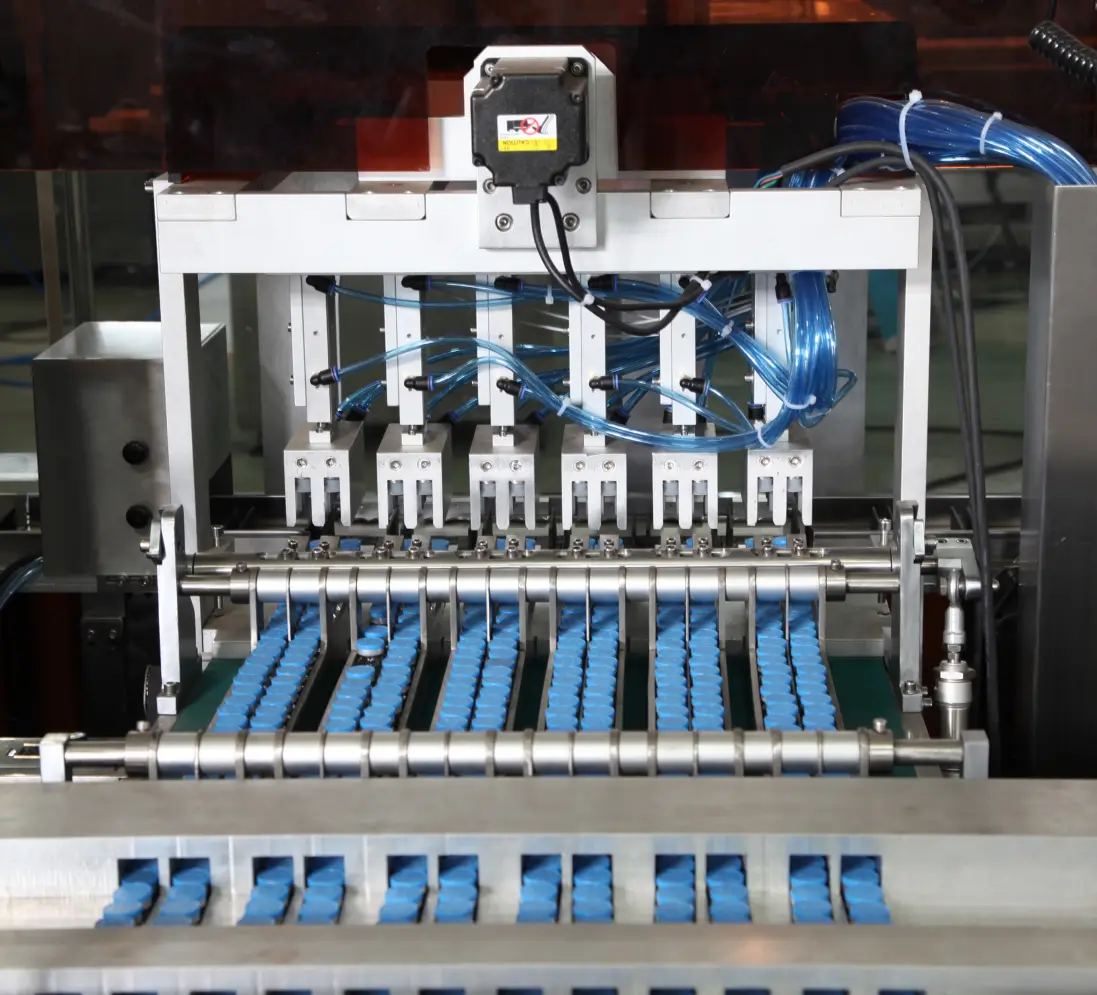

This machine can realize: bottle feeder, automatic bottle filling, carton unfolding, manual folding, medicine bottle and manual packing, carton sealing, etc.

Equipped with advanced computer control system, to achieve product statistics, equipment operating status statistics, failure maintenance index and various packaging materials supplement detection, alarm and emergency automatic shutdown, to ensure the safe and accurate operation of the production line.

Use mechanical (or visual) detection of medicine bottles, and automatically eliminate waste products. Each defective product and waste removal place is equipped with a movable collection device, and the packaging process is equipped with an isolation device to prevent the material from being damaged by pollution. The transmission area of the equipment is completely separated from the packaging area, and the structure is simple, easy to change and adjust, clean, fast and easy to maintain. Certification in full compliance with GMP production standards

Medicine bottle automatic feeding, automatic adding instructions, automatic sealing box. The manual can be automatically folded, and can be automatically docked with the bottle process (labeling machine), the whole machine automatic monitoring point, the machine running condition can be reflected on the display screen at any time, and the fault can be automatically stopped and reflected in the fault position of the touch screen and its causes.With advanced configuration, more than 90% of the electrical components of the whole machine are imported well-known brands.

It integrates feeding, bottle filling and box filling with compact structure and simple operation.PLC programmable control, touch man-machine interface.

Various packaging storage silos are equipped with alarm devices; It has fault stop protection and can display the fault cause and fault location. It is equipped with a reasonable buffer system to ensure that the shutdown phenomenon is low, so that it can maintain the normal operation of production when other equipment is shut down, so as to improve the work efficiency of the entire production line.

Product description

Company Introduction

Located in wen zhou, Wenzhou Urban Machinery Co., Ltd., short for Urban Machinery, is a production company. We are mainly engaged in the business of Capsule Filling Machine,Tablet Press Machine,Blister Packing Machine,Automatic Counting Machine,Liquid Filling and Capping Machine,Cartoning Machin,Other Packing Machine. Our company has always adhered to the corporate tenet of 'technological innovation, environmental protection, and faithful management', and achieved good social and economic benefits. Urban Machinery has a highly educated and professional technical team. Our team members provide related technical support according to production demand, so as to promote the production of quality products. With many years of practical experience, Urban Machinery is capable of providing comprehensive and efficient one-stop solutions.

We hope to cooperate with you for a win-win situation and jointly create a better future.