Wholesale Pharmaceutical Manufacturing Equipment Suppliers Urban Machinery Brand

Product details of the pharmaceutical manufacturing equipment suppliers

Product Information

Urban Machinery pharmaceutical manufacturing equipment suppliers is manufactured by using the high quality raw materials. These high performance and well-selected raw materials are bound to highlight the value of this product. The product is fabricated under strict quality control and its quality is stable enough. With strong technical strength, Urban Machinery can ensure the bulk production of pharmaceutical manufacturing equipment suppliers.

Product details

The automatic suppository filling production line has a stable and efficient manufacturing process, filling, freezing, sealing and other production processes to complete the whole process, and the production capacity is 8,000-12000 grain/hour.

Production process:

Make shell-Filling-Cooling-Sealing-Print production date etc.-Triangleand easy to tear dotted line-Cutting

(the number of cutting grains can be set arbitrarily on the touch screen, 1-10 grains can be cut at will)

Product parameters:

| Model | SJ-7LS |

| Output | 8,000 -12000pcs/h |

| single dosage | 0.5—5ml |

| Dosage allowed | <±2% |

| Packaging Film | PVC\PE (thickness0.15-0.18mm) |

| Stirring tank capacity | 70L |

| Air pressure | ≥0.6Mpa |

| Air consumption/min | 1.5m3/min |

| Water consumption/h | 50kg (recycling) |

| Working voltage | 3 phase 380V |

| total power | 7.5KW |

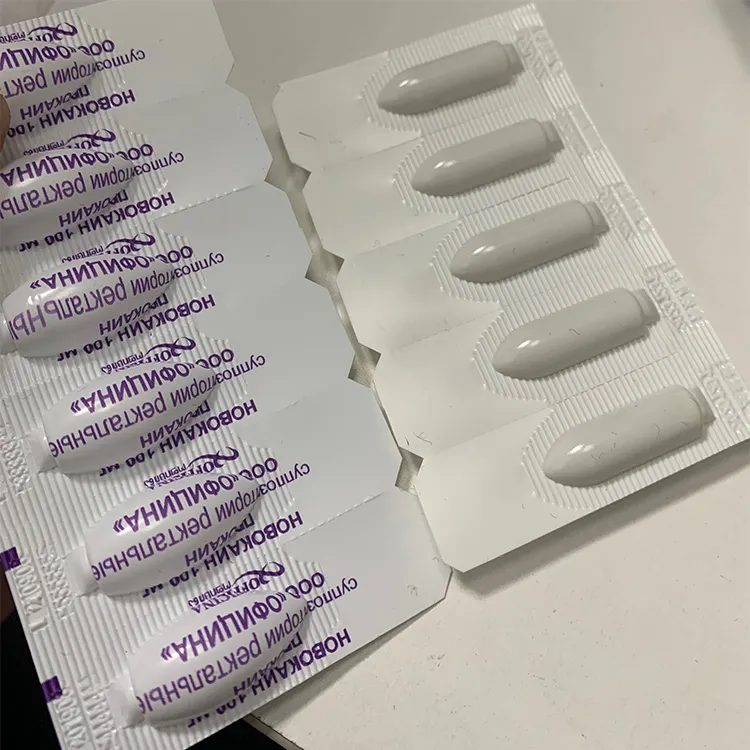

| Adopt forming shapes | Bullet, torpedo and other shapes |

| Machine Weight | 2000KG |

| Each distance of suppository | 17.4mm |

| Overall dimensions | L5,302mm×W2,120mm×H1,809mm |

| Adapt Material | Synthetic fatty acid glycerol, glycerin gelatin, polyethylene glycol etc |

Product description

Sample

Company Feature

• Since the beginning in our company has been focusing on the production and research of Capsule Filling Machine,Tablet Press Machine,Blister Packing Machine,Automatic Counting Machine,Liquid Filling and Capping Machine,Cartoning Machin,Other Packing Machine with rich experience.

• Our company has our own scientific research team and technical personnel. They can surely guarantee for our product quality.

• We keep our promises and treat our customers as supreme guests. Without prejudice to the interests of both parties, we try our best to provide our customers with the best, most reasonable and most warm-hearted services.

It is an honor for Urban Machinery to receive your consultation. We look forward to reaching long-term partnership with you.